-

SR526D SR536D Hydraulic Piling Rig , Rotary Piling Machine With Crawler Chassis

- Driving shed reinforced structure strong and shock resistant.

- Max stroke of hammer can recache 5.5m (Standard pilling stroke height up to 3.5 meters)

- Guide rail equipped with double-row; chain makes machine high safety coefficient.

- High frequency hydraulic hammer with borer pole diameter 85mm impact power up to 1400 joules.

- Equipped with angle digital indicator to adjust angle quickly.

- Guard rail vertical to the ground when piling, can most reduce the effect of vibration on pile perpendicularity.

- Driving shed reinforced structure strong and shock resistant.

- High control accuracy of operation valve Easy and smooth.

- The crawler chassis is equipped with protection and make safety first.

-

Trench Cutting Re-mixing Deep Wall Machine

TRD Method – Process Principle

1、Principle: After the chain-blade cutting tool is cut vertically and continuously to the design depth, it is pushed horizontally and injected with cement slurry to form a continuous, equal thickness and seamless cement wall;

2、Insert core material (H-shaped steel, etc.) into the cement mixing wall of equal thickness to form a composite retaining and water stop structure.

-

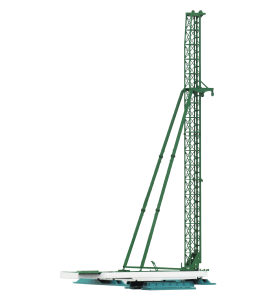

FOOT-STEP PILING RIG

360°rotation

Grounding voltage is low

Widely used

High stability

The most stable construction pile frame

Can be paired with multiple devices

Extremely cost effective

Optional height to meet different pile types

-

HYDRAULIC PILE HAMMER, PILING RIG

Energy saving and efficient

Good stability

High machining accuracy

The cooling speed of the oil cylinder is fast

Double barrel fast pile driving oil cylinder

Slender hammer body with strong penetration force

Independent circulating pump unit heat dissipation

Environmentally friendly, non-smoking, low noise

-

TR368HC 65m Rotary Rig Machine For Deep Hole Rock

TR368Hc is a classic deep hole rock drilling rig, which is the latest generation product for the development of medium to large pile foundations; Suitable for pile foundation engineering of urban engineering and medium to large bridges.

-

Strong Rock Rotary Head Drilling Rig TR360HT High Configuration

TR360HT is a high configuration strong rock drilling rig that can handle rock and soil, suitable for high-rise buildings and medium-sized buildings Pile foundation engineering for bridges. High efficiency, low cost and high reliability can be achieved in the construction of medium-sized Pile foundation Piling operation.

-

TR308H ROTARY DRILLING RIG

TR308H is a classic medium-sized drilling rig that has both economic and efficient functional advantages, as well as strong rock drilling ability; Especially suitable for construction of medium-sized Pile foundation in East China, Central China and Southwest China.

-

100m Deep Hole Rotary Foundation Drill Rig TR368HW

TR368Hw is a classic deep hole drilling rig, which is the latest generation product developed for medium and large pile foundations. The maximum pressure can reach 43 tons, which can meet the requirements of the full casing construction method. it is suitable for urban engineering and pile foundation engineering of medium and large bridges.

-

SQ200 RC crawler drilling rig

Reverse circulation drilling, or RC drilling, is a form of percussion drilling that uses compressed air to flush material cuttings out of the drill hole in a safe and efficient manner.

SQ200 RC full hydraulic crawler RC drilling rig is used by mud positive circulation, DTH-hammer, air lift reverse circulation, Mud DTH-hammer suit with suitable tools.

-

TR228H ROTARY DRILLING RIG

TR228H is a stare industrial and civil construction rig, which is suitable for Pile foundation of urban subway, middle and high-rise buildings, etc. This model can achieve low headroom and is suitable for special construction scenarios such as low factory buildings and bridges.

-

SNR2200 Hydraulic Water Well Drilling Rig

The SNR2200 water well drilling rig is a crawler type fully hydraulic top drive water well drilling rig, mainly used for drilling and drilling various types of water wells, geothermal air conditioning holes, detection wells, directional holes, precipitation wells, hot spring wells, filling holes, and other drilling and drilling operations. This drilling rig can use various construction techniques such as air down-the-hole hammer drilling and mud drilling. It has advantages such as wide adaptability to geology, high construction accuracy, fast drilling speed, good hole forming effect, easy operation, strong machine stability, and low failure rate, which are highly favored by customers.

-

professional supplier of

construction machinery equipment

- info@sinovogroup.com

- +86-10-51908781(9:00-18:00)+86-13801057171(other time)