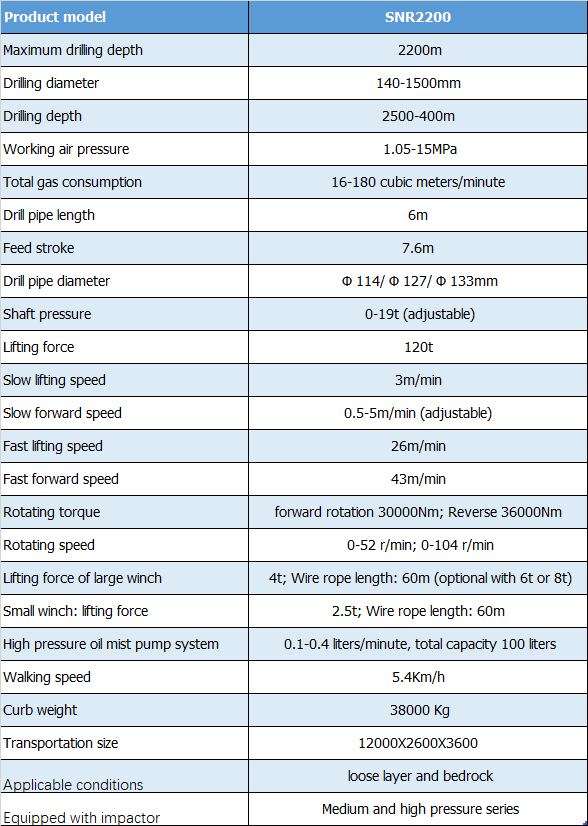

Technical Parameters

1. The Cummins engine (557 HP) is equipped with a constant power high-pressure load sensitive variable plunger pump system imported from Germany, which ensures that the power of the drilling rig is surging while achieving the effect of energy conservation and emission reduction, and greatly improves the cost performance of the drilling rig.

2. The combination of load sensitive plunger variable pump, original Bosch Rexroth M7 multi way valve from Germany, original Eaton low-speed high torque hydraulic motor from the United States, and patented high-performance reducer ensures the high performance and reliability of the drill.

3. The multi pump combined flow technology maximizes the reduction of system heat and fuel consumption, while make fast forward drilling speed of up to 43m/min and lifting speed of up to 26m/min, greatly improving labor efficiency and reducing construction costs.

4. Equipped with dedicated support leg valve for cranes, the entire machine is equipped with four high support legs with distance of 1.7 meters. When transported over long distances, there is no need to lift, and four high legs can be used to directly board the vehicle for convenient transportation. During construction, while ensuring reliable and stable support for the drilling rig, two inner support legs with a support force of up to 50t ( total 100t) and two short support cylinders are equipped with the mast, totaling up to 8 support points, Greatly improve the stability and construction accuracy of the drilling rig during construction operations.

5. Equipped with rotatable operating platform with hydraulic push rod rain cover, it not only provides humanized construction protection but also broadens the field of view, making construction more convenient.

6. The drilling rig is equipped with a rod unloading cylinder with a torque of up to 50000N. M, which reduces labor intensity and makes loading and unloading of drill pipes more convenient and efficient.

7. The sliding frame is a truss structure, with a rotating head stroke of up to 7.6m. Equipped with proprietary technology such as lifting the rotating center and a large triangle reverse lifting structure, the drilling rig is subjected to more reasonable forces, and the wear of moving parts is greatly reduced. The drilling accuracy is greatly improved, while lowering the 6-meter casing is no longer troublesome, and the stability and construction efficiency are greatly improved.

8. The application of special technology piston rod in high-pressure propulsion oil cylinder not only improves the reliability of the oil cylinder, but also achieves a lifting force of 120 tons. Equipped with an imported rotary motor (with a torque of up to 30000N. M), it can easily cope with various complex formations.

9. The proprietary high-pressure lubrication pump system solves the problem of difficult lubrication of drilling tools during deep hole drilling, greatly improving the service life of drilling tools and reducing construction costs.

10. The buffer sleeve between the power head equipped with an anti detachment structure and the transition connecting rod is a floating structure, which can avoid pulling and pressing during the unloading and makeup of the drill pipe, improve the service life of the drill pipe thread, and avoid economic losses caused by the fracture of the connecting rod.

11. Carefully designed precise and adjustable propulsion shaft pressure, propulsion speed, and rotational speed. It can achieve micro adjustment of feed, lifting, and rotation speeds to avoid sticking accidents. It can achieve simultaneous rotation, lifting or feeding, reducing the situation of stuck and jumping drilling, reducing accidents in the hole, and improving the ability to release the stuck.

12. The configuration of large and small double winches enables various auxiliary construction processes to be carried out simultaneously, reducing auxiliary time and improving work efficiency.

13. The independently adjustable hydraulic oil radiator ensures that the hydraulic oil no longer generates high temperatures during continuous operation of the drilling rig.

14. During operation, the mast can be fixed to the vehicle body, equipped with a professional level and a dedicated centering device to ensure the accuracy of the opening.

15. According to customer demand, construction equipment such as generator and high-pressure foam pump (maximum pressure up to 20Mpa) can be optionally installed to make your construction more convenient.

Technical parameters

Main attachment facilities

1. 190 pitch wide 600mm tracked chassis with steel track shoes.

2.410kw Cummins engine+ Bosch Rexroth 200 imported from Germany × 2 load sensitive plunger variable dual pumps.

3. The control valve for the main operation functions such as walking, turning and propulsion is the original Bosch Rexroth M7 multi way valve from Germany.

4. Swivel to the original American Eaton low-speed high torque cycloidal hydraulic motor+high-performance gearbox with patented technology.

5. The main supporting accessories are well-known brands in relevant domestic industries.

6. The main and auxiliary winches, including one 4-ton winch and one 2.5-ton winch, are equipped with a 60 meter steel wire rope.

7. The promotion chain is the plate chain of Hangzhou Donghua Brand.

8. Multiple optional configurations are available for users to choose from.

Optional drill accessories

1. Drilling tools, reaming tools.

2. Drill pipe lifting auxiliary tool, casing lifting auxiliary tool.

3. Drill pipe, drill collar, and guide.

4. Air compressors, turbochargers.

Technical documents

The water well drilling rig is shipped with a packing list, which includes the following technical documents:

Product Qualification Certificate

Product User Manual

Engine instruction manual

Engine warranty card

Packing list

Other

It is recommended to use screw air compressor with large air volume with pressure of more than 32kg. Recommended brands: Atlas, Sullair. Sullair currently has 1250/1525 dual working conditions for diesel displacement and 1525 electric displacement; Atlas currently has 1260 and 1275 diesel engines.

Drilling tools, can match 10 inch impactor, 8 inch impactor, 10 inch (or 12 inch) impactor, and supporting reaming and pipe drilling tools, as well as multiple drill bits required for each aperture. It is recommended to use a guide joint for the rear joint of the impactor, and preferably a guide joint for the front joint. The drill bit is equipped with fishing threads. If necessary, the impactor is equipped with a guide sleeve. The specific drilling tools and accessories that need to be purchased should be determined based on the construction plan, well design drawings, and geological conditions.

Jobsite

Work in Russia

Casing Diameter:700mm

Depth: 1500m

Work in ShanDong China

Drilling Diameter: 560mm

Depth: 2000m