Technical Parameters

|

Technical Specification |

||||||

|

Item |

Unit |

YTQH1000B |

YTQH650B |

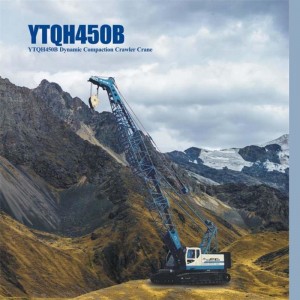

YTQH450B |

YTQH350B |

YTQH259B |

|

Compaction capacity |

t.m |

1000(2000) |

650(1300) |

450(800) |

350(700) |

259(500) |

|

Hammer weight permit |

t.m |

50 |

32.5 |

22.5 |

17.5 |

15 |

|

Wheel tread |

mm |

7300 |

6410 |

5300 |

5090 |

4890 |

|

Chassis width |

mm |

6860 |

5850 |

3360(4890) |

3360(4520) |

3360(4520) |

|

Track width |

mm |

850 |

850 |

800 |

760 |

760 |

|

Boom length |

mm |

20-26(29) |

19-25(28) |

19-25(28) |

19-25(28) |

19-22 |

|

Working angle |

° |

66-77 |

60-77 |

60-77 |

60-77 |

60-77 |

|

Max.lift height |

mm |

27 |

26 |

25.96 |

25.7 |

22.9 |

|

Working radius |

mm |

7.0-15.4 |

6.5-14.6 |

6.5-14.6 |

6.3-14.5 |

6.2-12.8 |

|

Max. pull force |

t.m |

25 |

14-17 |

10-14 |

10-14 |

10 |

|

Lift speed |

m/min |

0-110 |

0-95 |

0-110 |

0-110 |

0-108 |

|

Slewing speed |

r/min |

0-1.5 |

0-1.6 |

0-1.8 |

0-1.8 |

0-2.2 |

|

Travel speed |

km/h |

0-1.4 |

0-1.4 |

0-1.4 |

0-1.4 |

0-1.3 |

|

Grade ability |

|

30% |

30% |

35% |

40% |

40% |

|

Engine power |

kw |

294 |

264 |

242 |

194 |

132 |

|

Engine rated revolution |

r/min |

1900 |

1900 |

1900 |

1900 |

2000 |

|

Total weight |

t.m |

118 |

84.6 |

66.8 |

58 |

54 |

|

Counter weight |

t.m |

36 |

28 |

21.2 |

18.8 |

17.5 |

| Main body weight | t.m | 40 | 28.5 | 38 | 32 | 31.9 |

| Dimensino(LxWxH) | mm | 95830x3400x3400 | 7715x3360x3400 | 8010x3405x3420 | 7025x3360x3200 | 7300x3365x3400 |

| Ground pressure ratio | mpa | 0.085 | 0.074 | 0.073 | 0.073 | 0.068 |

| Rated pull force | t.m | 13 | 11 | 8 | 7.5 | |

| Lift rope diameter | mm | 32 | 32 | 28 | 26 | |

Product Introduction

Strong power system

It adopts 194 kW Cummins diesel engine with strong power and Emission Standard Stage III. Meanwhile, it is equipped with 140 kW big power variable main pump with high transmission efficiency. It also adopts high-strength main winch with strong fatigue resistance, which can effectively extend the working time and improve the working efficiency.

High lifting efficiency

It increases main pump displacement volume and adjusts valve group to provide more oil to hydraulic system. Thus, the energy conversion rate of the system has been greatly improved, and the main lifting efficiency has been increased by more than 34%, and the operating efficiency is 17% higher than the similar products of other manufacturers.

Low fuel consumption

Our company series dynamic compaction crawler crane can make sure that every hydraulic pump makes the best of the engine power in order to reduce the energy loss and realize energy resource saving by means of optimizing the entire hydraulic system. The energy consumption can be reduced by 17% for each single working cycle. The machine has intelligent working mode for different work phase. The pump group displacement can automatically be changed according to the machine working conditions. When the engine is in idling speed, the pump group is in minimum displacement for maximum energy saving. When the machine starts to work, the main pump displacement automatically adjust to the optimum state of displacement for avoiding energy waste.

Attractive appearance and comfortable cab

It has well-designed attractive appearance and wide view. The cab is mounted with shock absorption device and protective screening. The pilot control operation can relieve driver‘s fatigue. It is equipped with suspension seat, fan and heating device which make a comfortable operation environment.

Hydraulic drive system

It adopts Hydraulic driving system. Smaller overall size, and lesser curb weight, smaller ground pressure, better passing ability and hydraulic energy-saving technology significantly reduces the engine‘s fuel consumption. Meanwhile, the hydraulic control operations are easy, flexible and efficient and are more convenient to combine with the electrical control, improving the automatic control level for the whole machine.

Multistage security devices

It adopts multistage safety protection and electric combination instrument, integrated control of engine data and automatic alarm system. It is also equipped with slewing locking device for upper carriage, anti-overturn device for boom, over-winding prevention for winches, micro movement of lifting and other safety devices to ensure safe and reliable work.