OEM Customized Boring Bar Lathe - TR60 Rotary Drilling Rig – Sinovo Detail:

Video

TR60 Main Technical Specification

Product Description

TR60 rotary drilling is new designed self-erecting rig, which adopts advanced hydraulic loading back technology, integrates advanced electronic control technology. The whole performance of TR60 rotary drilling rig has reached advanced world standards.

The corresponding improvement on both structure and control, which makes the structure more simple and compact the performance more reliable and operation more humanized.

It is suitable for the following application:

Drilling with telescopic friction or interlocking Kelly bar – standard supply.

Features and advantages of TR60

The rotary head has the function of spin off speed; the maximum rotation speed can reach to 80r/min. It completely solves the problem of soil off difficulty for small diameter pile hole construction.

The main and auxiliary winch are all located on the back of mast which are easy to observe the direction of the rope. It improves the mast stability and construction safety.

Cummins QSB3.9-C130-31 engine is chosen to meet the state III emission requirements with economic, efficient, environmentally friendly and stable characteristics.

The hydraulic system adopts the international advanced concept, specially designed for the rotary drilling system. Main pump, rotary head motor, main valve, service valve, travelling system, rotary system and the joystick are all import brand. The auxiliary system adopts the load-sensitive technology to realize the on-demand distribution of the flow. Rexroth motor and balance valve are chosen for the main winch.

It is no need to disassemble the drill pipe before transporting. The whole machine can be transported together.

All the key parts of the electric control system (such as display, controller, and the inclination sensor) adopt international famous brands EPEC from Finland, and use aviation connectors to make special products for domestic projects.

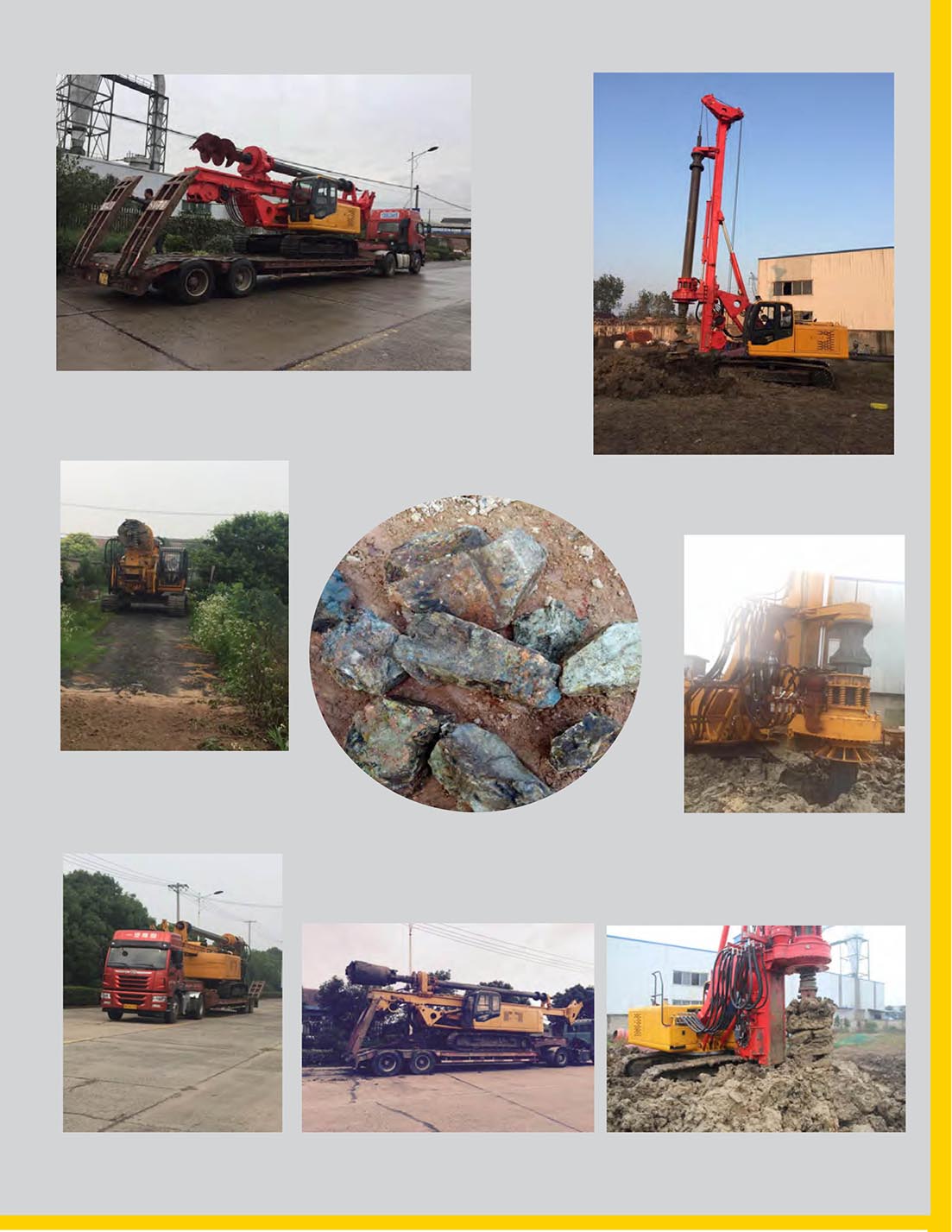

Construction Cases

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for OEM Customized Boring Bar Lathe - TR60 Rotary Drilling Rig – Sinovo, The product will supply to all over the world, such as: Jamaica, Kuala Lumpur, Nicaragua, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

-

China New Product Timber Auger Drill Bits - TR...

-

OEM/ODM Supplier Wire Rope Hoist - CQUY100 Hyd...

-

China Manufacturer for Mini Digger Concrete Bre...

-

Hot New Products Combined Pile Raft Foundation ...

-

Discountable price Gantry Hoist - CQUY100 Hydr...

-

Factory Supply Pile Diameter Size - 450-2000mm...