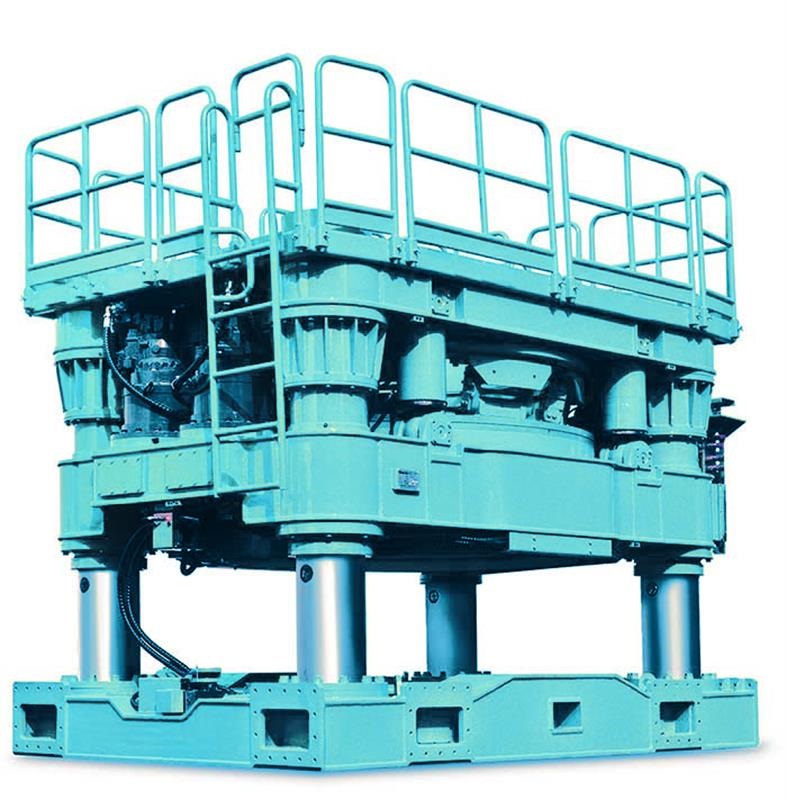

Manufactur standard Heavy Mallet Hammer - Casing Rotator – Sinovo Detail:

Technical Parameters

| TR1305H | |||

|

Working device |

Diameter of drill hole |

mm |

Φ600-Φ1300 |

| Rotary torque |

KN.m |

1400/825/466 Instantaneous 1583 |

|

| Rotary speed |

rpm |

1.6/2.7/4.8 |

|

| Lower pressure of sleeve |

KN |

Max.540 |

|

| Pulling force of sleeve |

KN |

2440 Instantaneous 2690 |

|

| Pressure-pulling stroke |

mm |

500 |

|

| Weight |

ton |

25 |

|

|

Hydraulic power station |

Engine model |

|

Cummins QSB6.7-C260 |

| Engine Power |

Kw/rpm |

201/2000 |

|

| Fuel consumption of engine |

g/kwh |

222 |

|

| Weight |

ton |

8 |

|

| Control mode |

|

Wired remote control/ Wireless remote control |

|

| TR1605H | ||

| Diameter of drill hole |

mm |

Φ800-Φ1600 |

| Rotary torque |

KN.m |

1525/906/512 Instantaneous 1744 |

| Rotary speed |

rpm |

1.3/2.2/3.9 |

| Lower pressure of sleeve |

KN |

Max.560 |

| Pulling force of sleeve |

KN |

2440 Instantaneous 2690 |

| Pressure-pulling stroke |

mm |

500 |

| Weight |

ton |

28 |

| Engine model |

|

Cummins QSB6.7-C260 |

| Engine Power |

Kw/rpm |

201/2000 |

| Fuel consumption of engine |

g/kwh |

222 |

| Weight |

ton |

8 |

| Control mode |

|

Wired remote control/ Wireless remote control |

| TR1805H | ||

| Diameter of drill hole |

mm |

Φ1000-Φ1800 |

| Rotary torque |

KN.m |

2651/1567/885 Instantaneous 3005 |

| Rotary speed |

rpm |

1.1/1.8/3.3 |

| Lower pressure of sleeve |

KN |

Max.600 |

| Pulling force of sleeve |

KN |

3760 Instantaneous 4300 |

| Pressure-pulling stroke |

mm |

500 |

| Weight |

ton |

38 |

| Engine model |

|

Cummins QSM11-335 |

| Engine Power |

Kw/rpm |

272/1800 |

| Fuel consumption of engine |

g/kwh |

216 |

| Weight |

ton |

8 |

| Control mode |

|

Wired remote control/ Wireless remote control |

| TR2005H | ||

| Diameter of drill hole |

mm |

Φ1000-Φ2000 |

| Rotary torque |

KN.m |

2965/1752/990 Instantaneous 3391 |

| Rotary speed |

rpm |

1.0/1.7/2.9 |

| Lower pressure of sleeve |

KN |

Max.600 |

| Pulling force of sleeve |

KN |

3760 Instantaneous 4300 |

| Pressure-pulling stroke |

mm |

600 |

| Weight |

ton |

46 |

| Engine model |

|

Cummins QSM11-335 |

| Engine Power |

Kw/rpm |

272/1800 |

| Fuel consumption of engine |

g/kwh |

216 |

| Weight |

ton |

8 |

| Control mode |

|

Wired remote control/ Wireless remote control |

| TR2105H | ||

| Diameter of drill hole |

mm |

Φ1000-Φ2100 |

| Rotary torque |

KN.m |

3085/1823/1030 Instantaneous 3505 |

| Rotary speed |

rpm |

0.9/1.5/2.7 |

| Lower pressure of sleeve |

KN |

Max.600 |

| Pulling force of sleeve |

KN |

3760 Instantaneous 4300 |

| Pressure-pulling stroke |

mm |

500 |

| Weight |

ton |

48 |

| Engine model |

|

Cummins QSM11-335 |

| Engine Power |

Kw/rpm |

272/1800 |

| Fuel consumption of engine |

g/kwh |

216 |

| Weight |

ton |

8 |

| Control mode |

|

Wired remote control/ Wireless remote control |

| TR2605H | ||

| Diameter of drill hole |

mm |

Φ1200-Φ2600 |

| Rotary torque |

KN.m |

5292/3127/1766 Instantaneous 6174 |

| Rotary speed |

rpm |

0.6/1.0/1.8 |

| Lower pressure of sleeve |

KN |

Max.830 |

| Pulling force of sleeve |

KN |

4210 Instantaneous 4810 |

| Pressure-pulling stroke |

mm |

750 |

| Weight |

ton |

56 |

| Engine model |

|

Cummins QSB6.7-C260 |

| Engine Power |

Kw/rpm |

194/2200 |

| Fuel consumption of engine |

g/kwh |

222 |

| Weight |

ton |

8 |

| Control mode |

|

Wired remote control/ Wireless remote control |

| TR3205H | ||

| Diameter of drill hole |

mm |

Φ2000-Φ3200 |

| Rotary torque |

KN.m |

9080/5368/3034 Instantaneous 10593 |

| Rotary speed |

rpm |

0.6/1.0/1.8 |

| Lower pressure of sleeve |

KN |

Max.1100 |

| Pulling force of sleeve |

KN |

7237 Instantaneous 8370 |

| Pressure-pulling stroke |

mm |

750 |

| Weight |

ton |

96 |

| Engine model |

|

Cummins QSM11-335 |

| Engine Power |

Kw/rpm |

2X272/1800 |

| Fuel consumption of engine |

g/kwh |

216X2 |

| Weight |

ton |

13 |

| Control mode |

|

Wired remote control/ Wireless remote control |

Introduction To Construction Method

The casing rotator is a new type drill with the integration of the full hydraulic power and transmission, and the combination control of machine, power and fluid. It is a new, environmentally-friendly and highly efficient drilling technology. In recent years, it is widely adopted in the projects such as the constructions of urban subway, articulation pile of deep foundation pit enclosure, clearance of waste piles (underground obstructions ), high-speed rail, road and bridge, and urban construction piles, as well as the reinforcement of reservoir dam.

The successful research of this brand new process method has realized the possibilities for the construction workers to conduct the construction of casing pipe, displacement pile, and underground continuous wall, as well as the possibilities for the pipe-jacking and shield tunnel to pass through the various pile foundations without barriers, when the obstructions, such as the gravel and boulder formation, cave formation, thick quicksand stratum, strong necking down formation, various pile foundation and steel reinforced concrete structure, are not removed.

The construction method of casing rotator has successfully completed construction missions of more than 5000 projects at places of Singapore, Japan, Hongkong District, Shanghai, Hangzhou, Beijing and Tianjin. It certainly will play a bigger role in the future urban construction and other pile foundation construction fields.

( 1 ) Foundation pile, continuous wall

Foundation piles for high-speed rail, road and bridge and house building.

Articulation pile constructions which are required to be excavated, such as subway platforms, underground architectures, continuous walls

Water retaining wall of reservoir reinforcement.

( 2 ) Drilling gravels, boulders and karst caves

It is allowable to conduct the foundation pile construction at mountain lands with gravel and boulder formations.

It is allowable to conduct operation and cast the foundation piles at he thick quicksand formation and necking down stratum or the filling layer.

Conduct rock-socketed drilling to the rock stratum, cast the foundation pile.

( 3 ) Clear the underground obstructions

During the urban construction and bridge rebuilding, the obstructions such as the steel reinforced concrete pile, steel pipe pile, H steel pile, pc pile and wood pile can be cleared directly, and cast the foundation pile on the spot.

( 4 ) Cut the rock stratum

Conduct the rock-socketed drilling to the cast-in-place piles.

Drill through-holes on the rock bed (shafts and ventilation holes)

( 5 ) Deep excavation

Conduct the in-place casting or steel pipe pile inserting for the deep foundation improvement.

Excavate deep wells for construction use in the constructions of reservoir and tunnel.

The advantages of adopting the casing rotator for construction

1)No noise, no vibration, and high safety;

2)Without mud, clean working surface, good environmental friendliness, avoiding the possibility for mud to enter the concrete, high pile quality, enhancing the bond stress of concrete to the steel bar;

3)During construction drilling, the characteristics of stratum and rock can be directly distinguished;

4)The drilling speed is fast and reaches about 14m/h for the general soil layer;

5)The drilling depth is large and reaches about 80m according to the situation of soil layer;

6)The hole forming verticality is easy to master, which can be accurate to 1/500;

7)No hole collapse will be caused, and the hole forming quality is high.

8)The hole forming diameter is standard, with little filling factor. Being compared with other hole forming methods, it can save a lot of concrete usage;

9)The hole clearing is thorough and fast. The drilling mud at the hole bottom can be clear to about 3.0cm.

Product Picture

Product detail pictures:

Related Product Guide:

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for Manufactur standard Heavy Mallet Hammer - Casing Rotator – Sinovo, The product will supply to all over the world, such as: United Arab Emirates, Canada, Lahore, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

-

Factory source Gearbox Hoist - CQUY55 Hydrauli...

-

factory low price Dynamic Compaction Of Soil -...

-

OEM/ODM Manufacturer 107mm Core Drill - XY-1A ...

-

PriceList for Foundation Engineering - SD2200 ...

-

Competitive Price for Rock Core Drilling Machin...

-

Massive Selection for 2 Hp Mud Pump - SHD350 h...