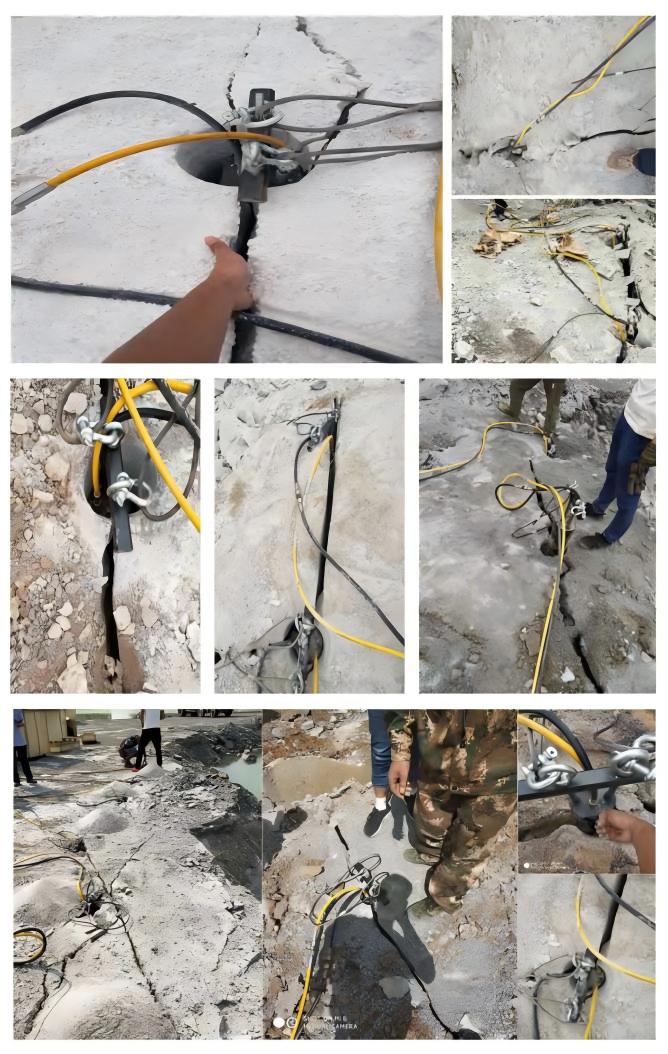

Splitter, also known as splitter, stone splitter, or rock breaker. It is a new method of mining that has developed rapidly in recent years. It’s vibration-free, impact-free, noise-free, and dust-free, completing splitting in seconds. It boasts high efficiency, controllable splitting, precise splitting dimensions, a moderate weight, simple operation, and easy maintenance. It can be used for demolition work indoors and in confined spaces.As a professional manufacturer company specializing in splitter products more than 10′years. Our products have exported to many countries with best price and top quality, and excellent service.

What’s the Splitter?

Every object has its own characteristics. Rock and concrete have extremely high external compressive strength, but very low tensile strength from the inside out, with a compressive-to-tensile strength ratio of 100:2 to 10, placing them in a brittle state. Hydraulic rock splitters capitalize on this brittleness by utilizing the wedge principle—releasing immense splitting force outwards from the narrowest possible opening. A hydraulic rock splitter consists of two main parts: a pump station and a splitter. During operation, high-pressure oil from the pump station drives the cylinders, generating tremendous thrust. This thrust extends the middle wedge in the wedge assembly forward, pushing the opposing wedges to the sides, thus splitting the object being split.

Compared to traditional methods in mining machinery areas, this product offers advantages such as simple structure, easy operation, high efficiency, low cost, safety, and energy efficiency. Compared to similar foreign products, it offers a highly cost-effective price (approximately one-quarter the price). This product is particularly suitable for the secondary disintegration of large rocks, making it an ideal alternative to blasting and manual disintegration.

The “Swiss Army Knife” of Engineering: The All-Round Application of Rock Splitter

1. Rock and Earthwork Engineering

Mining: Suitable for crushing hard rocks such as granite and basalt, with a drilling spacing of up to 3-5 meters; Tunnel construction: Static fracturing is achieved in confined spaces to avoid damage to the structure caused by blasting; Municipal engineering: Used for concrete demolition, road and bridge pile foundation treatment, etc., with a single split thickness of up to 800mm.

2. Stone Mining and Processing

High-End Decorative Stone Mining: Used in granite, marble, sandstone, and other precious stone quarries for the integrity separation and preliminary shaping of raw blocks, greatly improving yield and economic benefits; Irregular Stone and Sculpture Blank Preparation:In the stone processing plant, raw stone blocks are precisely split and divided to meet the customized needs of slabs, sculpture blanks, and architectural components of specific specifications.

3. Concrete Structure Demolition:

Conventional Structure Demolition: Efficiently demolish various types of plain concrete and reinforced concrete structures, such as building foundations, beams, columns, floor slabs, and shear walls; Complex and Confined Space Demolition: Specialized in static demolition tasks in enclosed or confined environments such as indoor spaces, underground areas, and equipment-intensive areas, including the precise removal of chimneys, diaphragm walls, and concrete column heads.

Resource Recovery Pre-treatment of Demolition Materials: At construction waste recycling sites, large-volume concrete components undergo secondary crushing to provide raw materials with ideal particle sizes for subsequent recycled aggregate production.

4. Metallurgical and Industrial Maintenance:

Smelting Facility Overhaul: Safely and efficiently complete the removal and overhaul of damaged linings in large smelting equipment such as aluminum electrolytic cells; Carbon Product Crushing: Used in carbon plants to crush hard carbon materials such as waste anode carbon blocks.

The Comprehensive Advantages of Rock Splitting Machines in Mining

1. Safety: Hydraulic rock splitters utilize the incompressible yet fluid properties of hydraulic oil, applying static thrust to achieve statically controllable operation. Therefore, no complex safety measures are required, and they do not generate the dangerous hazards associated with blasting or other impact demolition and rock drilling equipment.

2. Environmental Friendliness: Hydraulic rock splitters are environmentally friendly demolition experts. During operation, they do not produce vibration, impact, noise, or dust, and the surrounding environment is unaffected. They can be used without interference, even in densely populated areas, indoors, during urban construction, or near sensitive equipment.

3. Economy: Sinovo Brand Hydraulic rock splitters have a high splitting force (maximum splitting force up to 800T), so a single operation takes only a few seconds and can work continuously without interruption, resulting in high efficiency. Their operating and maintenance costs are very low, and they do not require the isolation or other time-consuming and expensive safety measures required for blasting operations.

4. Usability: Hydraulic rock splitters feature a user-friendly design, small size, light weight, and compact structure. It ensures simple and easy-to-learn operation, requiring only one person; it can be easily used for demolition and splitting indoors or in confined spaces; it can also operate underwater. Maintenance is convenient, and it has a long service life.

5. Precision: Unlike most traditional demolition methods and equipment, the hydraulic splitter can precisely determine the splitting direction in advance, achieving precise demolition and splitting according to the desired split shape and the size of the portion to be removed.

The rock splitter operates without vibration, impact, noise, dust, or debris, ensuring uninterrupted operation even in densely populated areas, indoors, or near precision equipment. Because it significantly increases the yield rate and is safe, environmentally friendly, economical, precise, and flexible, the rock splitter is an ideal product that can completely replace manual rock splitting for secondary decomposition of small areas. Sinovo Group has proven its product technology and superior quality through over ten years of market experience and customer reputation.

With the increase in mining projects and earthwork projects, I believe that our safe, efficient, and reliable construction rock splitters can provide strong support for rockwork projects as more professional and advanced engineering machinery, enabling them to be carried out efficiently.

Post time: Dec-09-2025