In the field of infrastructure construction, horizontal directional drilling rigs, as a highly efficient and environmentally friendly trenchless construction equipment, are gradually becoming the “main force” in projects such as underground pipeline laying and communication fiber optic cable crossing. As a professional horizontal directional drilling rig manufacturer, we are committed to equipment technology research and development and advanced manufacturing, and promote high-quality products globally, providing fast, reliable and green solutions for infrastructure projects in different countries and regions.

I. What is a Horizontal Directional Drilling Rig?

A horizontal directional drilling rig is a specialized engineering machine that lays underground pipelines without excavating the surface. Through processes such as guiding, drilling, reaming, and pullback, it achieves this. Thanks to its unique construction principle, it effectively avoids surface obstacles (such as roads, rivers, and buildings), minimizing damage to the surrounding environment while significantly shortening the construction period and reducing project costs. Compared to traditional open-cut construction methods, horizontal directional drilling rigs offer significant advantages, including eliminating the need for large-scale excavation, high construction efficiency, minimal environmental impact, and strong adaptability. They are widely used in various fields such as municipal engineering, telecommunications, gas, petroleum, and water conservancy.

II. Wide Range of Applications of Horizontal Directional Drilling Rigs

Municipal Pipeline Construction: In urban water supply, drainage, and sewage pipeline laying projects, horizontal directional drilling rigs can efficiently complete underground pipeline construction without damaging urban roads and green belts, avoiding traffic congestion and environmental damage caused by excavation.

Telecommunications and Power Engineering: Used for underground laying of communication optical cables and power cables, especially suitable for scenarios with high requirements for surface integrity, such as urban core areas and highways, ensuring the stability and safety of communication and power transmission.

Gas and Oil Pipeline Installation: In the laying of gas pipelines and oil transportation pipelines, horizontal directional drilling rigs can cope with complex geological conditions, achieving precise laying of long-distance, large-diameter pipelines, ensuring efficient and reliable energy transportation.

Water Conservancy and Agricultural Irrigation: Suitable for the construction of farmland irrigation pipelines and water conservancy pipelines, contributing to agricultural modernization and water conservancy infrastructure construction, reducing the occupation and damage to farmland.

III. Unique and personalized design features, optimized functions to meet customers’ needs for efficient construction

1. In the African market, our horizontal directional drilling rigs have undergone special optimization design for the local arid, dusty climate and complex geological conditions, such as strengthening the equipment’s dustproof system and improving the engine’s ability to adapt to high-temperature environments, to ensure that the equipment can still operate stably under harsh working conditions and efficiently assist in the construction of local municipal pipeline and communication projects.

2. In our Central American project, we earned high praise from our clients for our professional technical solutions and customized services. As a well-known infrastructure company, our local clients had extremely high requirements for construction precision and equipment components, especially in the selection of reaming bits, where they set stringent standards. Based on their needs and the local geological conditions (primarily clay and gravel layers), we recommended our company’s latest fluted reamer. (Image of the fluted reamer attached.)

This fluted reamer boasts three core advantages: High chip removal efficiency: The unique flow channel design quickly removes cuttings generated during drilling, preventing clogging and effectively increasing reaming speed while minimizing downtime.

Strong wear resistance: Utilizing high-strength alloy materials and a special heat treatment process, the drill bit’s cutting edge exhibits higher hardness and greater wear resistance, significantly extending its service life in complex geological conditions such as sand and gravel layers, reducing the cost and frequency of replacement parts for customers.

Precise reaming accuracy: The precise structural design ensures uniform hole diameter during reaming, effectively guaranteeing smooth pipeline pullback and avoiding rework due to hole diameter deviations, thus improving overall construction quality.

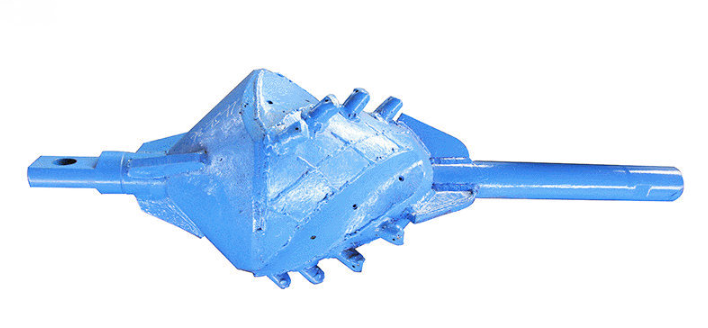

3. To cope with emergencies, we added a booster to the drilling rig, as shown in the attached diagram

For example, SINOVO brand SHD135 directional drilling rig can increase the thrust-pull force from 1350kN to 2000kN when dealing with sudden stuck drill bits, which is very practical. In order to reduce the labor intensity of workers, the drilling rig is equipped with a fully lifting robotic arm, which enables quick and flexible replacement of drill rods and greatly improves construction efficiency.

4.The drilling rig features a design combining wireless remote control for movement and a fully enclosed cab operation, greatly enhancing the customer’s driving comfort and experience. The tracks are made of steel with plastic pads, allowing for travel on various road surfaces without damaging them. IV. Customer Satisfaction Feedback: On-site Photos Witness Quality

The horizontal directional drilling rig is equipped with our professionally designed fluted reamer. After arriving at the construction site and being put into use, the equipment’s excellent performance exceeded the customer’s expectations. (Attached are on-site photos.)

The drilling accuracy and construction efficiency fully meet the project requirements. Appropriate drill bits and tools are matched according to different geological conditions. The superior product quality and professional technical service result in an excellent customer experience and satisfaction. Customers have commented that “the horizontal directional drilling rig’s performance far exceeded our expectations. It is easy to operate and powerful. In particular, the recommended fluted reamer offers fast chip removal, wear resistance, and durability, completely solving the problems of low reaming efficiency and easy drill bit damage we encountered in previous construction projects. Since the equipment was put into use, there have been no malfunctions, significantly shortening the construction cycle and saving us substantial costs.” The horizontal directional drilling rig has entered several overseas markets, injecting strong momentum into local infrastructure projects.

Post time: Nov-28-2025